-

Heat Resistant Stainless steel metal fiber

Stainless steel metal fibers and yarns provide excellent shielding against static electricity in a wide range of applications. They are widely used in the textile industry (spun yarn), filtration (sintered felt or needle-punched felt) and other industries. These materials are utilized for producing pure spinning yarn from stainless steel fibers, and creating blended yarn with traditional textile fibers (such as cotton, polyester, or wool) to enhance the anti-static, conductive, and high-strength properties of the yarn.

-

Stainless steel fiber breaking sliver

Stainless steel fibers for the anti-static textile industry

Stainless steel metal fibers and yarns provide excellent shielding against ESD in a wide range of applications. Stainless steel metal fiber is a stretchbroken sliver of very fine stainless steel fibers. They can be blended with all spun fibers at the spinning mill to obtain anti-static yarns in a wide range of yarn numbers. Woven fabrics, tufted and woven carpets, knitted and braided fabrics, and needle-punched felts are made

permanently electrostatically controlled when small quantities of stainless steel metal fibers are blended with the textile material.Stainless steel metal fiber has superior washing characteristics (high durability) and fulfills EN1149-1, EN1149-3, EN1149-5 and EN61340-5-1. Thanks to its superior conductive properties, the garment does not charge.

-

PBO long filaments

PBO filament is an aromatic heterocyclic fiber composed of rigid functional units and has a very high orientation along the fiber axis. The structure gives it ultra-high modulus, ultra-high strength, and excellent temperature resistance, flame retardant, chemical stability, impact resistance, radar transparent performance, insulation and other application properties. It is a new generation of super fiber used in aerospace, national defense, rail transportation, electronic communications and other fields after aramid fiber.

-

PBO staple fiber

Take PBO filament as raw material,it was crimped,shaped, cutted by professional equipment. Feature of temperature resistant of 600 degree, with good spunability, cutting resistance, which widely used in fields of special technical fabric, fire rescue clothing, high temperature filter belt, heat restistant belt, aluminum and heat resistant shock absorbing material (glass processing).

-

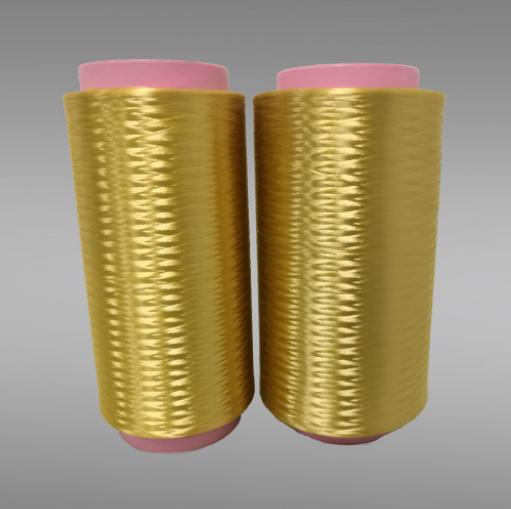

metal fiber spun yarn

Metal fiber yarn is a range of single or multi-ply spun yarns. The yarns are a blend of silver staple fiber with cotton、ployester or aramid fibers.

This mix results in an efficient, conductive medium with antistatic and conductive properties. Featuring thin diameters, silver fiber staple spun yarns are very

flexible and light,guarantees the safety and quality of your products.

Contents:ployester +metal fiber / cotton +metal fiber / Cotton+silver staple fiber/aramid + metal fiber etc

Yarn Counts: Ne5s, Ne10s, Ne18s, Ne20s, Ne24s, Ne30s, Ne36s, Ne40s, Ne50s, Ne60s, etc. (single yarn and ply yarn) -

Silver staple fiber 5% with 95 % cotton spun conductive yarn

Silver fiber blended yarn is a range of single or multi-ply spun yarns. The yarns are a blend of silver staple fiber with cotton、ployester or aramid fibers.

This mix results in an efficient, conductive medium with antistatic and conductive properties. Featuring thin diameters, silver fiber staple spun yarns are very

flexible and light,guarantees the safety and quality of your products. The spun

yarns processed into a correct fabric configuration meet the international

EN 1149-51 , EN 61340, ISO 6356 and DIN 54345-5 standards as well the

OEKO-TEX® and REACH regulations that restrict harmful substances. -

Nomex IIIA flame retardant yarn

Meta aramid (Nomex) characterized by good fire resistance and high strength. properties of meta aramid at a temperature of 250 degrees the materiasl can keep stable for a long time.

Meta aramid yarn composition: 100% meta-aramid yarn, 95% meta-aramid+5%para-aramid, 93%meta-aramid+5%para-aramid+2%antistatic,contents meta aramid +flame retardant viscose 70+30/60+40/50+50,meta aramid+ modacrylic+ cotton etc,yarns count and flame retardant fibers can be specified by customer.

Color: raw white, fiber dope dyeing and yarn dyeing.

All flame retardant fibers can be mixed with any multi-component, with tight spinning, Siro spinning, Siro tight spinning, air spinning, bamboojoint device.