Product

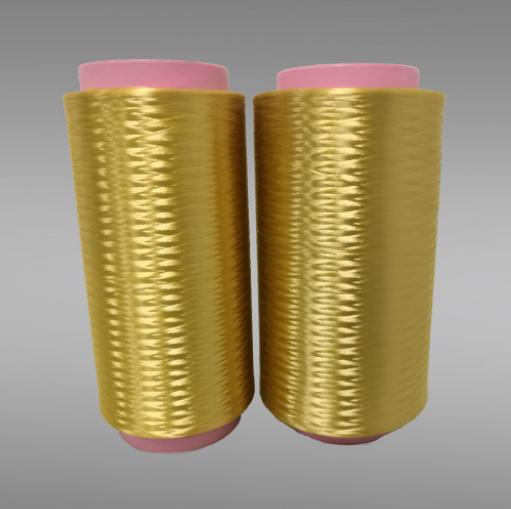

PBO long filaments

PBO Filament

PBO filament is an aromatic heterocyclic fiber composed of rigid functional units and has a very high orientation along the fiber axis. The structure gives it ultra-high modulus, ultra-high strength, and excellent temperature resistance, flame retardant, chemical stability, impact resistance, radar transparent performance, insulation and other application properties. It is a new generation of super fiber used in aerospace, national defense, rail transportation, electronic communications and other fields after aramid fiber.

PBO, for poly(p-phenylene-2,6-benzobisoxazole)

PBO,for poly(p-phenylene-2,6-benzobisoxazole) is a special material in fibres with high mechanical and thermal performance.

Its mechanical properties are more than aramid fiber, with the advantages of ultra-high strength modulus, PBO fiber has excellent flame retardant and thermal resistance its (degradation temperature : 650°C, working temperature 350°C-400°C ), itultra-low dielectric loss, transmission and light spun ability, PBO fiber has wide application prospects in aerospace, national defense, police and fire fighting equipment, rail transit, electronic communication and civil protection.

It is one of the most typical dual-use key strategic materials in contemporary society.

PBO long filaments

|

Unit |

Part No |

|||

|

SLHS-11 |

SLHS -12 |

SLHM |

||

|

Appearance |

Light yellow |

Light yellow |

Light yellow |

|

|

Density |

g/cm' |

1.54 |

1.54 |

1.56 |

|

Liner Density |

220 278 555 |

220 278 555 |

216 273 545 |

|

|

dtex |

1110 1670 |

1110 1670 |

1090 1640 |

|

|

Moisture regain |

% |

≤4 |

≤4 |

≤2 |

|

Oil Length |

% |

0~2 |

0~2 |

0~2 |

|

Tensile strength |

cN/dtex |

≥36 |

≥30 |

≥36 |

|

GPa |

≥5.6 |

≥4.7 |

≥5.6 |

|

|

Tensile modulus |

CN/dtex |

≥1150 |

≥ 850 |

≥ 1560 |

|

GPa |

≥ 180 |

≥ 130 |

≥240 |

|

|

Elongation at break |

% |

3.5 |

3.5 |

2.5 |

|

Decomposition temperature |

°C |

650 |

650 |

650 |

|

LOI(limit oxygen index) |

% |

68 |

68 |

68 |

PBO long filaments available specification

Specification of filaments available: 200D,250D,300D,400D,500D,750D,1000D,1500D

Application

Transport belt, rubber hose and other rubber products reinforcing material;

Reinforcement components for ballistic missiles and composites;

The tension parts of fiber optic cables and the protective film of fiber optic cables;

Reinforced fiber of various flexible wires such as hot wires and headphone wires;

High tensile materials such as ropes and cables.