E-WEBBINGS®: Narrow Woven Fabrics for the IoT

Technology Sector

The Internet of Things (IoT) — a vast network of devices such as computers, smartphones, vehicles, and even buildings embedded with electronics that allow them to exchange data with one another — is becoming more and more popular and widely known. As its prominence increases, so too does the demand for smart textiles, or e-textiles — fabrics made with conductive fibers that allow electronics and digital parts to be embedded in them. For instance, the fingertips of smartphone-capable gloves use conductive fibers to transmit electrical impulses from the user’s body to the screen despite the lack of direct contact. Frequently used within the IoT industry, e-textiles comprise the integrals market — components necessary for optimal data communication in our modern environment. The wearables market, meanwhile, is comprised of monitoring-capable devices and clothing such as the smartphone-capable gloves mentioned above.

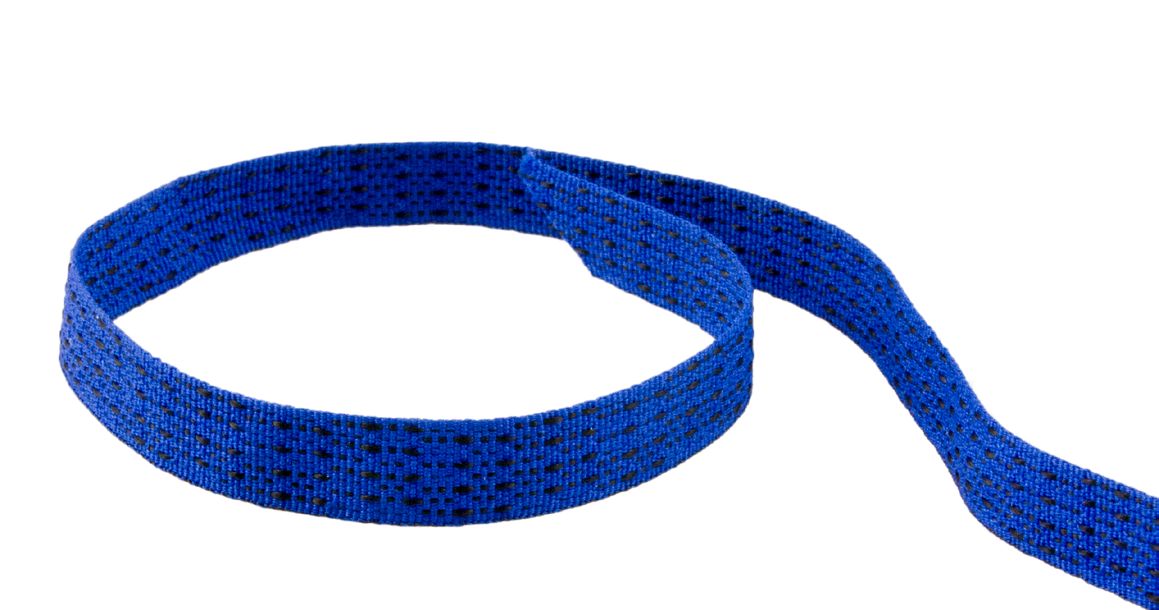

Bally Ribbon Mills is a leading designer, manufacturer, and supplier of high-quality specialty fabrics, including e-textiles such as our engineered E-WEBBINGS® product line, which is specially designed for use in a wide range of integral and wearable products. Made from a wide variety of fibers and conductive elements, E-WEBBINGS® provide structural and conductive components that allow for the detection and gathering of various types of data — everything from temperature and electric currents to distance and speed, depending on the application.

Bally Ribbon Mills is a leading designer, manufacturer, and supplier of high-quality specialty fabrics, including e-textiles such as our engineered E-WEBBINGS® product line, which is specially designed for use in a wide range of integral and wearable products. Made from a wide variety of fibers and conductive elements, E-WEBBINGS® provide structural and conductive components that allow for the detection and gathering of various types of data — everything from temperature and electric currents to distance and speed, depending on the application.

What is Conductive Fiber?

As mentioned above, e-textiles incorporate conductive fibers into their weave. Conductivity can be achieved several ways. Metal strands can be used directly in the woven product. Common materials used here include carbon, nickel, copper, gold, silver, or titanium which are capable of conducting electricity or, occasionally, heat. Non-conductive fibers such as cotton, nylon, or polyester can be altered to impart conductivity. There are two methods for combining these conductive fibers with other base fibers.

The first method is more direct: Super-thin metal strands, or metal-coated material strands, are commingled directly with the filaments of another yarn forming a uniform and cohesive fiber

The other method, meanwhile, involves spinning a fiber as usual and then using it as a substrate, impregnating it with a metal-based powder. Both production methods allow for the fibers to pick up and transfer electrical signals throughout a part or garment, carrying them to a central location for processing and evaluation. In metal powder varieties, conduction is facilitated by an even distribution of metal particulates throughout the entire fiber; in metal strand spun varieties, the physical shape of the fibers allows for a vast network of physical connections. Conductive fibers of both varieties have been proven highly effective when used to make e-textiles.

What is an E-Textile?

Depending on whether they are used in the integrals or wearables market, e-textiles may also be referred to as “smart fabrics,” “smart garments,” or “electronic textiles.” Regardless of what they are called, every e-textile is made of conductive fibers woven throughout the base material. Depending on their intended use, e-textiles may also include digital components, such as batteries and small computer systems that create electric currents and track feedback from the textile. Bally Ribbon Mills uses enhanced performance e-textiles for our E-WEBBINGS® line. E-WEBBINGS® products are designed to provide a wide range of sophisticated capabilities — our materials provide the structure for products that perform tasks ranging from body temperature tracking and regulation to environmental hazard tracking and medical monitoring for automated drug release purposes. E-WEBBINGS® can also be utilized in various non-wearable applications.

Depending on whether they are used in the integrals or wearables market, e-textiles may also be referred to as “smart fabrics,” “smart garments,” or “electronic textiles.” Regardless of what they are called, every e-textile is made of conductive fibers woven throughout the base material. Depending on their intended use, e-textiles may also include digital components, such as batteries and small computer systems that create electric currents and track feedback from the textile. Bally Ribbon Mills uses enhanced performance e-textiles for our E-WEBBINGS® line. E-WEBBINGS® products are designed to provide a wide range of sophisticated capabilities — our materials provide the structure for products that perform tasks ranging from body temperature tracking and regulation to environmental hazard tracking and medical monitoring for automated drug release purposes. E-WEBBINGS® can also be utilized in various non-wearable applications.

How Are E-Textiles Used?

Extremely versatile, e-textiles are used in a wide range of industries and applications, including:

E-textiles are used in a number of applications in the medical industry, with more currently under study

For example, e-textiles are used to track patient vital signs, as well as monitor heart rate, respiration, temperature, and even physical activity. Used in conjunction with wearable devices, these tools can directly notify the patient or doctor that medication or injections are needed — before visible identifiers can be seen.

E-textiles are also currently being researched for potential use in helping to restore patients’ sensory perception; it’s believed that conductive fibers can be used to detect pressure levels, exterior non-body temperature, and vibration, and then translate those input measurements into brain-detectable signals.

When incorporated into garments, e-textiles can serve protective purposes.

Relevant to a diverse range of industries, from mining and refineries to power generation, e-textiles can be designed, incorporating Bally Ribbon Mills’ E-WEBBINGS®, to alert wearers to hazardous environments, notifying people of rising or dangerous levels of chemicals, gasses, and even radiation. E-textiles can also use a wearer’s vital signs to determine if the person is suffering from fatigue, as pilots and long-haul truck drivers often do.

Garments made with E-WEBBINGS® can also be invaluable in military settings. Aside from monitoring soldiers’ vital signs, E-WEBBINGS® designs can aid in communications and even communicate on the wearer’s behalf, relaying location and health information. For instance, providing the impact location in the event of explosions or gunfire can help prepare responding medics before they even arrive at the scene.

Most of the applications discussed so far have fallen into the wearables category — a huge market with tremendous potential — but e-textiles are also invaluable in the integral market. For instance, e-textiles are often used for material shielding, particularly for sensitive electronic parts. This shielding can be used in two ways. The first method is similar to how an e-textile such as E-WEBBINGS® functions in a protective garment; in order to prevent damage to delicate equipment, an e-textile shield can detect adverse environmental conditions — an abnormally high level of water vapor, for example — and alert the equipment operator. Secondly, e-textile shielding can also be used as a more literal shield, generating actual high-frequency shielding to protect electronics from electrically generated radio frequency interference

Post time: Jun-14-2023